The Ultimate Guide to Production Optimization in Manufacturing

Understanding Production Optimization

In the competitive world of manufacturing, production optimization is a crucial element that can significantly impact a company's bottom line. It involves enhancing the efficiency and effectiveness of a production process while maintaining high-quality standards. By optimizing production, manufacturers can reduce waste, lower costs, and improve product output. The ultimate goal is to create a streamlined, cost-effective process that meets customer demands without unnecessary expenditure.

Key Elements of Production Optimization

To achieve effective production optimization, several key elements must be considered. These include process analysis, resource management, and technology integration. Process analysis involves examining existing workflows to identify bottlenecks and areas for improvement. Resource management focuses on the efficient use of materials, labor, and equipment to maximize output while minimizing waste. Finally, technology integration entails incorporating advanced manufacturing technologies such as automation and data analytics to enhance productivity.

The Role of Automation in Optimization

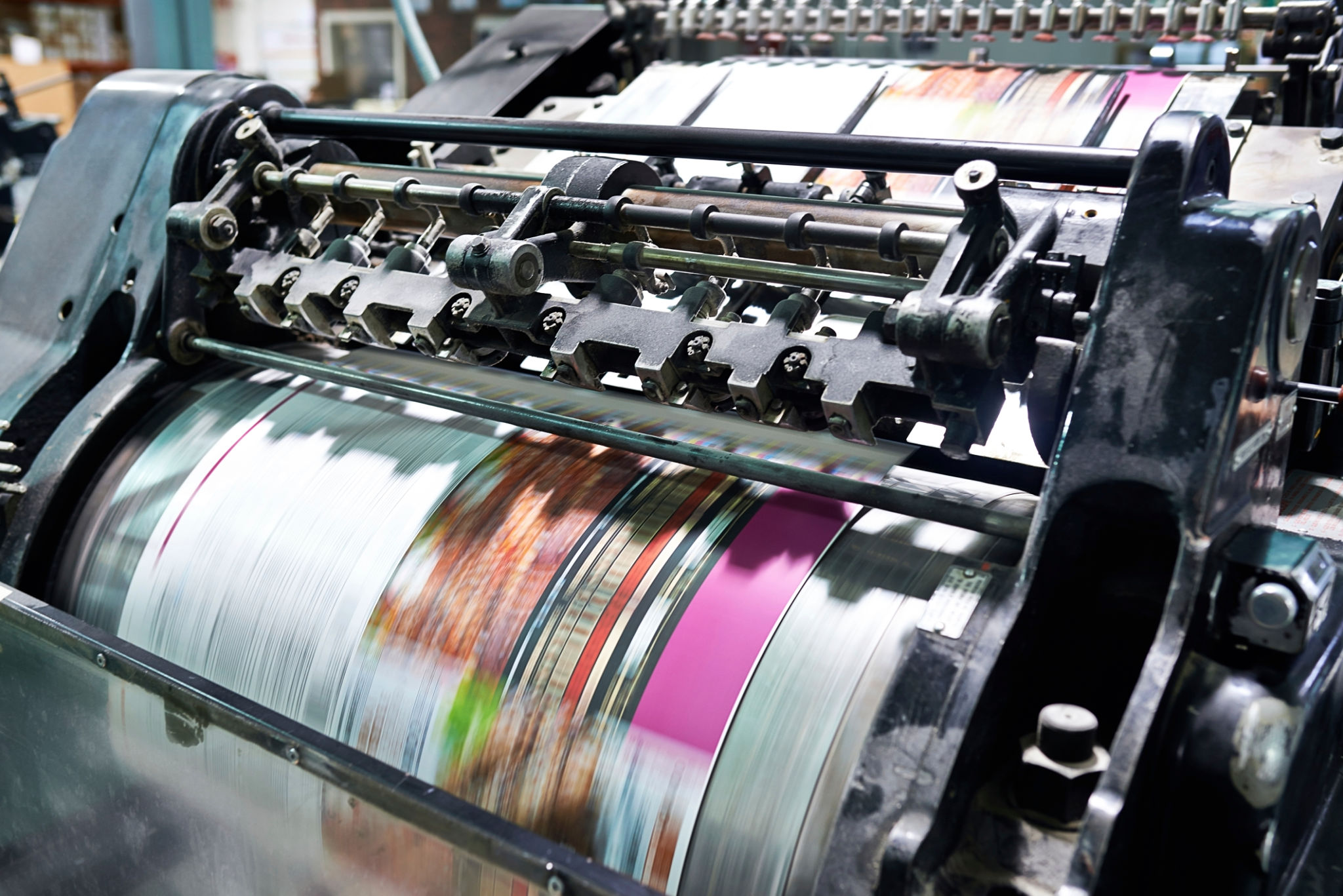

Automation plays a vital role in production optimization by reducing manual labor and increasing precision. Implementing automated systems can lead to faster production times and consistent product quality. For instance, using robotics for repetitive tasks can free up human workers to focus on more complex activities that require critical thinking and problem-solving skills. Additionally, automation can help in maintaining accuracy and reducing errors, which can significantly lower production costs.

Implementing Data-Driven Strategies

Data-driven strategies are essential for identifying opportunities for improvement in the production process. By collecting and analyzing data from various stages of manufacturing, companies can gain valuable insights into their operations. This information can be used to make informed decisions about process adjustments, resource allocation, and technology investments. Predictive analytics can further enhance this by forecasting potential issues before they arise, allowing for proactive measures to be taken.

Sustainability and Its Impact on Production

Sustainability has become an increasingly important consideration in production optimization. Manufacturers are now focusing on reducing their environmental footprint by implementing eco-friendly practices. This includes reducing energy consumption, minimizing waste, and sourcing sustainable materials. By prioritizing sustainability, companies not only contribute to environmental conservation but also unlock new efficiencies and cost savings that can enhance their competitive advantage.

Measuring Success in Production Optimization

To measure the success of production optimization efforts, it is essential to establish clear metrics and benchmarks. Key performance indicators (KPIs) such as cycle time, yield rate, and overall equipment effectiveness (OEE) can provide valuable insights into the efficiency of the production process. Regular monitoring and analysis of these metrics allow manufacturers to identify trends, evaluate the impact of changes implemented, and make necessary adjustments to maintain optimal performance.

The Future of Production Optimization

The future of production optimization lies in the continued advancement of technology and innovation. With the rise of Industry 4.0, manufacturers are increasingly adopting smart manufacturing practices that leverage the Internet of Things (IoT), artificial intelligence (AI), and machine learning. These technologies enable real-time monitoring and control of production processes, leading to greater flexibility and responsiveness to market demands. As these technologies evolve, they will further transform the landscape of manufacturing optimization.

In conclusion, production optimization is a multifaceted approach that requires ongoing attention to process improvements, technology adoption, and sustainable practices. By focusing on these areas, manufacturers can achieve significant gains in efficiency and productivity while remaining competitive in a rapidly changing industry landscape.